In today’s article, we will take a closer look at the remarkable strength of Flex Seal and specifically focus on its weight capacity. Flex Seal, a widely recognized and trusted brand, has gained popularity for its ability to seal, bond, and repair various surfaces. However, many have wondered just how much weight this remarkable product can bear. By exploring the weight capacity of Flex Seal, we aim to shed light on its durability, empowering you to make informed decisions when it comes to choosing the right adhesive for your projects.

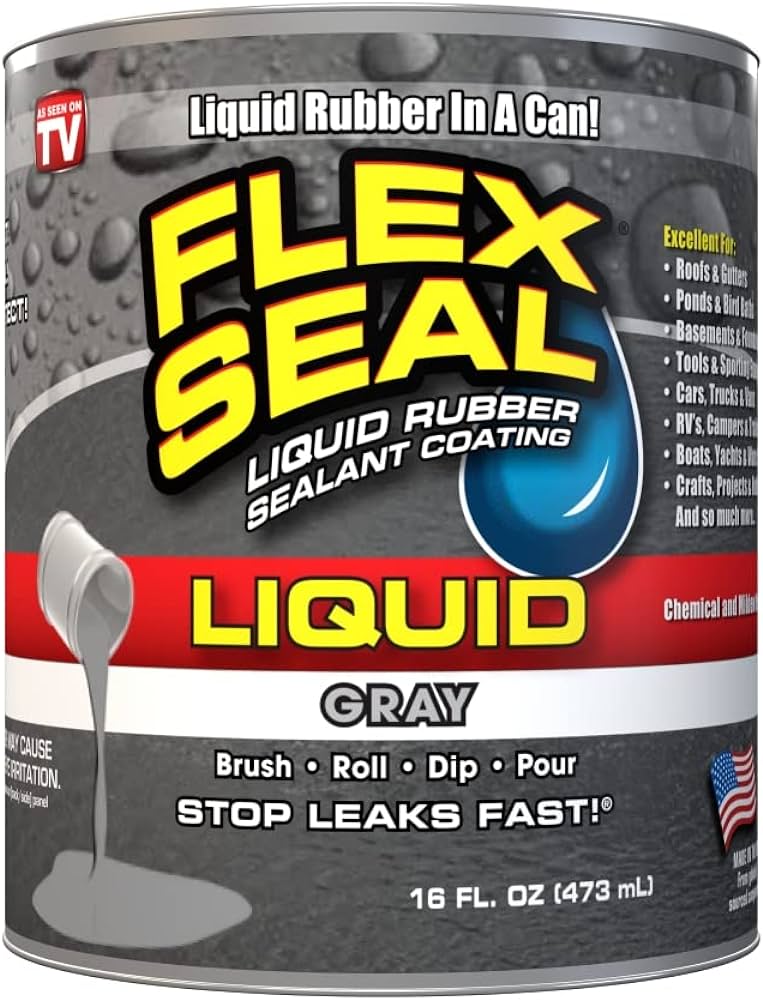

This image is property of Amazon.com.

Understanding Flex Seal

What is Flex Seal?

Flex Seal is a versatile, rubberized coating product that is designed to provide a waterproof and airtight seal on a variety of surfaces. It is known for its ability to create a flexible barrier that seals out moisture, air, and even sound. With its unique formula, Flex Seal has gained popularity as a reliable solution for various home improvement and repair projects.

Introduction to Flex Seal products

Flex Seal offers a range of products, each specially formulated to cater to different needs and applications. The product line-up includes Flex Seal Liquid, Flex Seal Spray, Flex Seal Tape, and Flex Seal Colors. Flex Seal Liquid is a thick, rubberized coating that can be brushed, rolled, or poured onto surfaces. Flex Seal Spray is an aerosol version that provides an easy and convenient way to apply the product. Flex Seal Tape is a strong, adhesive tape that creates a durable, waterproof seal. Flex Seal Colors, available in a variety of shades, allows users to match their project with the desired color.

Properties of Flex Seal

Flex Seal possesses several key properties that make it a reliable choice for sealing and protecting various surfaces. One of its most notable properties is its flexibility, which allows it to conform to different shapes and sizes without cracking or losing its effectiveness. Additionally, Flex Seal is resistant to harsh weather conditions, making it suitable for both indoor and outdoor use. It also exhibits excellent adhesion to a wide range of materials, including concrete, metal, wood, plastic, fabric, and more. Moreover, Flex Seal is known for its longevity, ensuring that the seal it creates remains strong and durable over time.

Factors Affecting Weight Capacity

Type of Flex Seal product

The weight capacity of Flex Seal can vary depending on the specific product used. While all Flex Seal products are designed to provide a strong and reliable seal, the weight capacity may differ due to variations in formulation and application method. It is important to carefully consider the intended use and weight requirements when selecting the appropriate Flex Seal product.

Application method

The method of application can also influence the weight capacity of Flex Seal. Proper surface preparation and thorough application are essential for achieving optimal results. Following the manufacturer’s instructions and using the recommended application techniques can help ensure the maximum weight capacity of the Flex Seal product.

Surface material and condition

The type of surface material and its condition are crucial factors that can affect the weight capacity of Flex Seal. While Flex Seal is compatible with a wide range of materials, different surfaces may have varying levels of porosity, texture, and strength. It is essential to evaluate the surface material and make any necessary preparations to ensure proper adhesion and weight-bearing capacity.

Environmental factors

Environmental conditions, such as temperature, humidity, and exposure to UV radiation, can impact the performance and weight capacity of Flex Seal. Extreme temperatures and high humidity levels may affect the curing process and the overall strength of the seal. Similarly, prolonged exposure to direct sunlight or harsh weather conditions can degrade the seal over time. Considering these environmental factors is crucial for maximizing the weight capacity and longevity of the Flex Seal application.

Weight Capacity Testing

Testing procedures

Flex Seal undergoes rigorous testing procedures to determine its weight capacity and performance. These testing procedures involve subjecting the product to various levels of weight and monitoring its ability to withstand the load without compromising the seal. Testing is conducted under controlled conditions to ensure consistency and accuracy in the results.

Third-party certifications

To uphold its reputation for reliability and quality, Flex Seal has obtained certifications from independent third-party testing laboratories. These certifications provide assurance to users that the weight capacity claims of Flex Seal have been verified and validated by reputable organizations. By obtaining these certifications, Flex Seal demonstrates its commitment to providing accurate and trustworthy information regarding its weight capacity.

Different weight classes

Flex Seal is tested for weight capacity across different weight classes, ensuring that the product can withstand a wide range of loads. This approach allows users to select the appropriate Flex Seal product based on their specific weight requirements. By offering multiple weight classes, Flex Seal caters to various applications and enhances its versatility.

Flex Seal Maximum Weight Capacity

Advertised weight capacity

Flex Seal’s maximum weight capacity is typically advertised on the product packaging and promotional materials. The advertised weight capacity provides a clear indication of the load limit that the product can sustain without compromising its sealing capabilities. This information is crucial for users who need to rely on Flex Seal for supporting or securing heavy objects or structures.

Understanding limitations

While Flex Seal offers a high weight capacity, it is essential to understand the limitations of the product. The weight capacity indicated on the packaging should be followed strictly, as exceeding this limit may compromise the integrity of the seal. It is advisable to thoroughly assess the weight requirements and consider additional reinforcement techniques if necessary.

Safety considerations

When utilizing Flex Seal for weight-bearing applications, safety considerations play a vital role. Users should take precautions and ensure that the weight being supported by the Flex Seal does not pose a risk to individuals or property. Regular inspections and maintenance are also recommended to ensure that the weight capacity remains within the limits and that the seal’s integrity is maintained.

Case studies and real-life applications

There have been numerous real-life applications where Flex Seal has successfully supported considerable weight. From securing heavy equipment to creating strong bonds between surfaces, Flex Seal has proven its ability to withstand substantial loads. Case studies and user testimonials highlight the successful implementation of Flex Seal in various weight-bearing situations, further reinforcing its reliability and effectiveness.

This image is property of Amazon.com.

Enhancing Weight Capacity

Surface preparation techniques

Proper surface preparation is crucial for enhancing the weight capacity of Flex Seal. Surfaces should be clean, dry, and free from any loose or flaking material. Any oil, grease, or dirt should be thoroughly removed to promote optimal adhesion. In cases where the surface is uneven or porous, additional surface preparation techniques, such as sanding or priming, may be necessary to enhance the weight-bearing capacity.

Multiple coats for increased strength

Applying multiple coats of Flex Seal can significantly enhance its weight capacity. Each coat adds an additional layer of strength and durability, creating a more robust seal. By allowing each coat to dry thoroughly before applying the next, users can maximize the weight capacity and ensure a stronger bond between the Flex Seal and the surface.

Reinforcing techniques

In situations where the weight requirements exceed the maximum capacity of Flex Seal, users can employ various reinforcement techniques. This may include the use of additional support structures or integrating other load-bearing materials in combination with Flex Seal. Reinforcing techniques should be applied carefully, ensuring they do not compromise the integrity or effectiveness of the product.

Combining different Flex Seal products

Combining different Flex Seal products can also enhance the weight capacity and provide more effective solutions for challenging weight-bearing applications. Using Flex Seal Liquid in conjunction with Flex Seal Tape, for example, can create a multi-layered seal that can withstand heavier loads. It is important to ensure compatibility between different Flex Seal products and follow the manufacturer’s guidelines when using them together.

Comparing Flex Seal to Other Products

Strength comparison with similar products

Flex Seal’s weight capacity can be compared to other similar products in the market. When evaluating the strength of different sealing and waterproofing products, it is essential to consider the specific weight capacity claims and testing certifications. Conducting a comprehensive comparison can help users make an informed decision based on their specific requirements.

Different weight capacity claims

Weight capacity claims may vary among different sealing and waterproofing products. It is important to review the specifications and weight limits provided by the manufacturer to ensure that the chosen product meets the desired weight-bearing requirements. Flex Seal’s advertised weight capacity provides users with a clear understanding of the loads it can support, making it easier to select the appropriate product.

Durability and longevity

Another factor to consider when comparing Flex Seal to other products is its durability and longevity. Flex Seal is renowned for its long-lasting performance, even in challenging conditions. By providing a robust and flexible seal, Flex Seal can withstand the rigors of daily use and maintain its effectiveness over time. Evaluating the durability and longevity of different products can help users determine which option is most suitable for their specific needs.

This image is property of Amazon.com.

Tips for Maximizing Weight Capacity

Proper application techniques

To maximize the weight capacity of Flex Seal, it is important to follow the proper application techniques provided by the manufacturer. This includes preparing the surface adequately, applying the product evenly and thoroughly, and allowing sufficient drying and curing time. Following these guidelines ensures that the Flex Seal adheres properly and provides the highest level of strength and durability.

Curing and drying time

Allowing adequate curing and drying time is essential for maximizing the weight capacity of Flex Seal. Rushing the process can compromise the integrity of the seal and reduce its overall strength. Users should refer to the manufacturer’s instructions for the recommended curing and drying times based on the specific Flex Seal product being used.

Temperature and humidity considerations

Temperature and humidity can significantly impact the curing and drying process of Flex Seal. It is crucial to consider these factors when applying the product, as extreme temperature variations or high humidity levels may affect the weight capacity and the overall performance of the seal. Ideal application conditions should be maintained to ensure optimal results.

Regular inspections and maintenance

To ensure that the weight capacity of Flex Seal remains intact over time, regular inspections and maintenance are necessary. Periodic checks can help identify any signs of wear, damage, or compromised seal integrity. Timely repairs or reinforcements can be made to maintain the weight-bearing capability and prolong the life of the Flex Seal application.

Applications and Uses

Common household applications

Flex Seal finds numerous applications in everyday household scenarios. From sealing leaking pipes and repairing damaged roofs to waterproofing gutters and fixing cracks in foundations, Flex Seal provides a versatile solution for a wide range of household repairs. Its ability to create a durable seal on various surfaces makes it a practical choice for homeowners seeking a reliable and long-lasting fix.

Industrial and commercial uses

Flex Seal’s strength and reliability also make it suitable for various industrial and commercial applications. It can be used to seal joints, protect against corrosion, and insulate equipment. Whether in construction, automotive, plumbing, or manufacturing industries, Flex Seal offers a cost-effective and efficient solution for addressing challenging sealing and waterproofing needs.

Unique and creative applications

Beyond its traditional uses, Flex Seal has also found its way into unique and creative applications. From creating art pieces to constructing custom molds, the versatility of Flex Seal allows for innovative and unconventional projects. Its strong adhesion and flexibility open up a world of possibilities, inspiring individuals to explore their creative side while enjoying the benefits of a reliable and durable seal.

This image is property of pdt-images.cdn.hardwareandtools.net.

User Experiences and Reviews

Customer testimonials

Users of Flex Seal often share their experiences and provide testimonials regarding the product’s weight capacity and overall effectiveness. These firsthand accounts offer valuable insights into the real-life applications of Flex Seal and the weight-bearing capabilities it provides. Customer testimonials can help potential users gain confidence in the product’s performance and make informed decisions based on the experiences of others.

Positive and negative feedback

In addition to testimonials, both positive and negative feedback play a crucial role in understanding the strengths and limitations of Flex Seal. Positive feedback highlights the successful weight-bearing applications, while negative feedback provides an opportunity for improvement and reveals potential challenges that users may encounter. Analyzing a variety of feedback enables users to gain a comprehensive understanding of the product and its weight capacity.

Comparisons with other products

Comparisons between Flex Seal and other similar products can also provide valuable insights into the weight capacity and performance of sealing and waterproofing solutions. By considering feedback and experiences with other products, users can make informed decisions and select the option that best meets their needs in terms of weight capacity, durability, and overall effectiveness.

Conclusion

Summary of findings

Flex Seal is a reliable and versatile product that offers various options for sealing and waterproofing applications. Understanding its weight capacity and the factors that can affect it is crucial for selecting the appropriate Flex Seal product and ensuring optimal performance. Along with proper application techniques and surface preparation, users can maximize the weight capacity and enjoy the benefits of a strong and durable seal.

Final thoughts on weight capacity

Flex Seal’s weight capacity is determined through rigorous testing procedures and certified by independent third-party organizations. The advertised weight capacity provides users with a clear indication of the load it can support, ensuring safety and reliability. By understanding the limitations and incorporating techniques such as surface preparation, multiple coats, and reinforcement, users can enhance the weight-bearing capabilities of Flex Seal.

Recommendations for appropriate uses

Flex Seal is recommended for various applications, including common household repairs, industrial and commercial uses, and unique creative projects. It provides a reliable seal on different surfaces and offers versatile options to suit specific weight-bearing requirements. By carefully considering the intended use and following the manufacturer’s guidelines, users can make informed decisions and utilize Flex Seal effectively for their sealing and waterproofing needs.

This image is property of Amazon.com.